Home / News / Industry News / Common Mistakes to Avoid When Using Automotive Body Adhesives

Home / News / Industry News / Common Mistakes to Avoid When Using Automotive Body Adhesives 2026-01-20

Automotive body adhesives have become an essential component in modern vehicle manufacturing and repair. From replacing panels to reinforcing structural components, adhesives provide advantages such as improved strength, reduced weight, and enhanced corrosion resistance compared to traditional mechanical fasteners like bolts and rivets. However, the performance of these adhesives is highly dependent on proper application techniques and conditions. Even minor mistakes can compromise adhesion, durability, and the overall safety of the vehicle. In this article, we explore common mistakes with automotive adhesives and provide practical guidance on how to apply automotive body adhesive correctly.

One of the most critical steps in using automotive body adhesives for car repair is surface preparation. Many users underestimate how significantly surface contamination or improper cleaning can affect bonding performance. Adhesives require a clean, dry, and chemically compatible surface to form a strong molecular bond.

Skipping Cleaning: Dirt, grease, oils, and waxes from manufacturing or previous repairs can prevent proper adhesion.

Using Incompatible Cleaners: Some solvents can leave residues or damage painted surfaces, reducing adhesive effectiveness.

Inconsistent Abrasion: Failing to roughen smooth surfaces can prevent the adhesive from mechanically interlocking with the substrate.

Best Practices:

Follow automotive body adhesive surface preparation tips: clean the bonding area with a manufacturer-recommended solvent or degreaser.

Lightly abrade smooth surfaces with fine-grit sandpaper to enhance mechanical adhesion.

Remove dust or particles after abrasion using lint-free cloths or compressed air.

Neglecting these steps is one of the most common reasons for adhesive failure in automotive applications.

Environmental conditions play a critical role when using automotive adhesives for structural bonding. Applying adhesives under unsuitable conditions can lead to poor curing, weak bonding, or long-term degradation.

Applying in Extreme Temperatures: Most adhesives have an optimal application temperature range. Too cold can slow curing, while excessive heat can cause premature skinning or sagging.

High Humidity: Some moisture-curing adhesives can cure too quickly or unevenly if humidity is too high.

Exposure to Dust or Debris: Contaminants in the air can settle on uncured adhesive, compromising the bond.

Best Practices:

Follow the adhesive manufacturer’s recommended temperature and humidity ranges.

Work in a clean, dust-free environment, or cover the adhesive immediately after application.

Store adhesives properly to avoid contamination before use.

By respecting environmental limitations, you can ensure consistent bonding and long-lasting performance.

Choosing the wrong type of adhesive is a common and costly mistake. Best automotive body adhesives for car repair vary in terms of curing chemistry, flexibility, and substrate compatibility. Using an incompatible product can lead to bond failure, material damage, or corrosion issues.

Rigid Adhesives on Flexible Panels: Applying a rigid epoxy on a highly flexible panel may cause cracking under vibration.

Non-Structural Adhesives for Load-Bearing Joints: Using general-purpose adhesives for structural bonding may compromise vehicle safety.

Ignoring Chemical Compatibility: Some adhesives may react negatively with specific plastics, coatings, or metals.

Best Practices:

Determine whether the application is structural or non-structural.

Check the manufacturer’s compatibility chart for materials like aluminum, steel, composites, or plastics.

Consider adhesive flexibility, strength, and cure time relative to the application.

Proper adhesive selection prevents long-term issues like delamination or failure under stress.

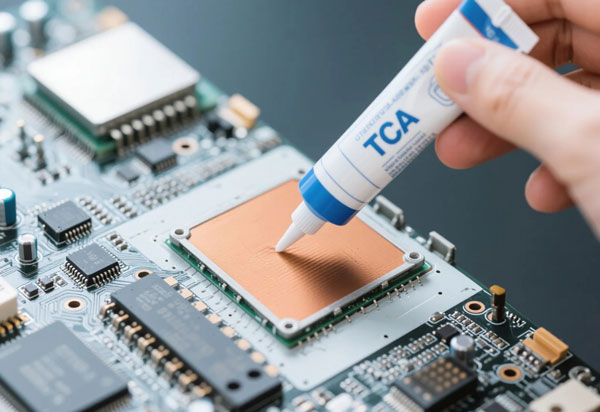

Both excessive and insufficient adhesive application can be problematic. Too little adhesive may result in weak joints, while too much can lead to squeeze-out, uneven curing, or poor aesthetics.

Over-Application: Excess adhesive can spill over edges, causing messy finishes or interfering with panel alignment.

Under-Application: Insufficient adhesive creates voids or dry spots, reducing structural strength.

Uneven Beads: Inconsistent bead thickness can lead to stress concentrations and early failure.

Best Practices:

Follow guidelines for bead size, pattern, and spacing when applying automotive body adhesives for structural bonding.

Use precise dispensing tools to control volume and distribution.

Check that the adhesive spreads evenly when panels are joined.

A controlled application ensures both structural integrity and professional appearance.

Curing is the chemical process by which adhesives achieve their full strength. Rushing this process or failing to respect the curing schedule is a frequent mistake.

Premature Handling: Moving or stressing bonded components before the adhesive fully cures can weaken the joint.

Ignoring Heat or Pressure Requirements: Some adhesives require heat, pressure, or clamping to cure properly.

Assuming Room Temperature Cure Is Enough: Certain structural adhesives need post-curing at elevated temperatures to reach full mechanical performance.

Best Practices:

Always consult the adhesive data sheet for cure times and conditions.

Use clamps, jigs, or fixtures to hold parts securely during curing.

Avoid load-bearing operations on newly bonded panels until the adhesive has fully set.

Proper curing ensures the adhesive achieves its intended strength and durability.

Even with the correct adhesive and preparation, improper joint design or panel alignment can compromise performance. Automotive panel bonding techniques are designed to work in specific joint configurations, and incorrect handling can create stress concentrations.

Misaligned Panels: Shifting or uneven panels can reduce contact area and weaken the bond.

Inappropriate Gap Design: Too wide or narrow joints can prevent proper adhesive flow and curing.

Lack of Backing or Support: Unsupported joints may deform during adhesive curing, reducing bond strength.

Best Practices:

Check panel alignment before applying adhesive.

Maintain recommended gap widths for the specific adhesive.

Use temporary supports or fixtures to maintain joint integrity during curing.

Attention to alignment and joint design reduces the likelihood of adhesive failure under vibration or load.

Many automotive adhesives contain reactive chemicals that can be hazardous if mishandled. Failing to use appropriate personal protective equipment (PPE) or ventilation is a frequent oversight.

Skipping Gloves or Eye Protection: Many adhesives are irritants and can damage skin or eyes.

Inadequate Ventilation: Solvent-based adhesives can release fumes that are harmful if inhaled.

Improper Storage: Some adhesives are flammable or chemically unstable if stored incorrectly.

Best Practices:

Wear gloves, safety glasses, and protective clothing when handling adhesives.

Work in well-ventilated areas or use fume extraction equipment.

Follow storage and disposal instructions to avoid accidents.

Safe handling protects not only the user but also the longevity and performance of the adhesive.

Many users assume that all automotive body adhesives behave the same under stress, but variations in temperature, load, and substrate can significantly affect performance. Skipping small-scale tests is a common error.

No Trial Runs: Applying adhesive to a critical component without prior testing can reveal unforeseen issues.

Ignoring Environmental Simulation: Not considering temperature cycles, moisture exposure, or vibration during testing can misrepresent adhesive performance.

Best Practices:

Conduct small-scale trials to evaluate adhesion strength on the actual materials.

Simulate environmental conditions where possible to ensure reliability.

Adjust application methods or materials based on test results.

Testing mitigates risks and provides confidence that the adhesive will perform under real-world conditions.

Using automotive body adhesives for car repair correctly requires attention to detail at every stage. Mistakes such as neglecting surface preparation, ignoring environmental conditions, using the wrong adhesive, improper application volume, insufficient curing, poor panel alignment, overlooking safety, and skipping testing can compromise joint integrity and vehicle safety.

By following automotive panel bonding techniques, applying adhesives carefully, and respecting curing schedules, technicians and DIY enthusiasts can achieve strong, durable, and safe bonds. This approach not only enhances the quality and longevity of repairs but also ensures that vehicles meet the safety standards expected in modern automotive engineering.